The water of the Soja River is suitable for sake brewing

Have you ever heard of a sake called “Yamatan Masamune?”

Its ginjo-shu was adopted by ANA's First Class in 2014 and has won gold medals at the National New Sake Competition every year.

This sake, which is also exported to 10 countries around the world, is actually made at the YAGI-SHUZOUBU, a long-established company that has been making sake in Imabari since the end of the Edo period.

And the water used for this Yamatan Masamune is the same subsoil water from the Soja River that makes the Imabari towels.

Because of this connection, IMABARI LIFE visited the YAGI-SYUZOUBU in Imabari City.

Nice to meet you. We also enjoy “Yamatan Masamune” every time we come to Imabari.It is a delicious sake that is fruity, easy to drink, and has a strong flavor.

President Nobuki Yagi(hereinafter honorific title omitted):Thank you very much. In Imabari, it is often sold in supermarkets and taverns.

I heard that this sake is made from subsoil water of the Soja River, the same river that makes Imabari towels.

Yagi:That's right. The sake brewery was built at the end of the Edo period(1603-1867)in a location with good water.

Oh, the water comes from this site? This is quite central in Imabari, isn't it?

Yagi:Yes, it is.This is about the end of the downstream most part of the Soja River, where it is fully filtered.

A little further and it is already seawater. Incidentally, I heard that when the Emperor Showa came to Ehime, he drank tea from water here.

So it has always been famous for its excellent water.Is the quality of the water suitable for making sake?

Yagi:Yes, the water in the Soja River is moderately soft. Good sake is usually made with medium-soft water.If the water is too soft, there are not enough minerals to nurture the yeast,and if the water is too hard, the sake will be kind of harsh.

The Soja River originates from the Takanawa mountain range in Ehime Prefecture.

The water is also used to bleach and dye Imabari towels.

Challenge of making sake

from local rice after returning home

Although you are the 8th generation of such a long-established company, you did not take over the company right away, did you?

Yagi:Yes. After graduating from university, I worked for an IT company as a consultant, and after eight years, I felt it was time to return home (laughs).

I understand that you have taken on various reforms since you came back.

Yagi:I thought about how to survive among so many good sake brands in Japan, and one of them was to stick to local ingredients.We tried a little every year,and now all of our brands, except for Daiginjo, are made with rice grown in Ehime prefecture.

Certainly, I think when people come to Imabari, they want to drink sake made with local rice.

“Matsuyama Mitsui" is used for ginjo-shu, which is mainly produced in Imabari, the local.

Delicious sake cannot be made without human hands

When you showed me the process, I realized that it is a very time-consuming work.

Yagi:That's right. Sake brewing involves the following processes:rice polishing, rice washing and soaking, steaming, koji making, yeast starter making, brewing, fermentation, pressing, filtration, and maturing. As has been the case since the previous generation, we cannot compete with the large companies that make sake in large quantities and sell it cheaply, so we feel the value of making good-tasting sake even in small quantities. For example, in the “steaming” process, we used to steam rice in larger quantities but that did not improve the quality of the steamed rice, so we switched to steaming the rice in small portions using a steamer.

“Steaming" is the process of steaming washed rice in a steamer.

The steamed rice is scooped out with a shovel and then cooled.

So you decided to make good products little by little. What was the president himself measuring the number of seconds right now?

Yagi:It was during the rice washing process. We washed rice and soaked it in water, and I counted the number of seconds it was soaked in the water.

“Washing rice" is done while accurately measuring the number of seconds the rice is soaked in water.

It is a surprisingly exacting process, isn't it?

Yagi:Yes, it is. The soaking time depends on the rice used.

Some of it was very chemical, and some of it was craftsmanship. It was amazing to see the scaffolding set up on top of the large tanks, and the craftsmen walking around on the scaffolding. I thought they looked like carpenters.

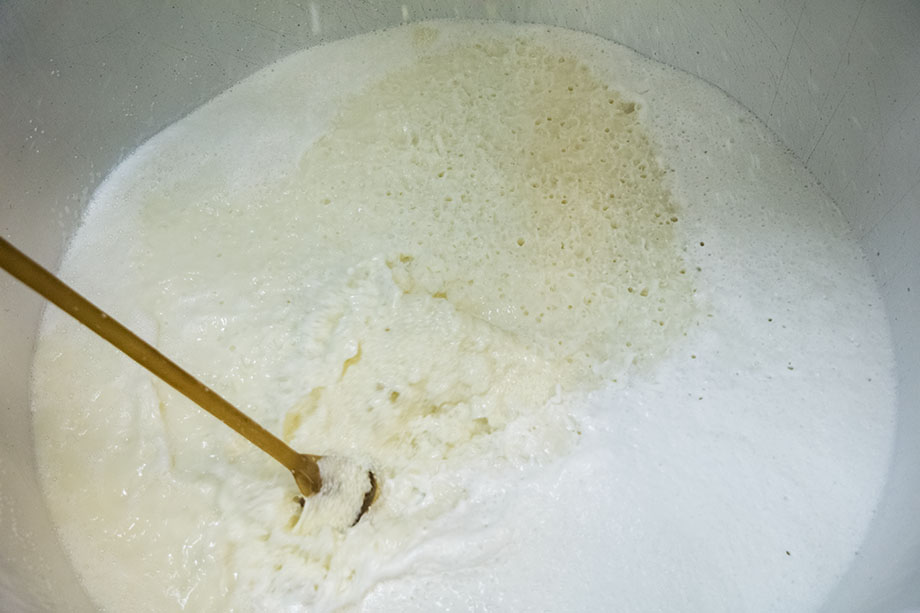

Yagi:It is the “brewing” process. This is the important process of mixing steamed rice, koji, and water. Craftsmen do this every day, so they are used to it.

We tried to get on top of that thing, but it was about 2 to 3 meters high, so it was very scary.

The “brewing” process of combining steamed rice, koji, and water

Recently, there has been a lot of talk about using computers to control the sake production process. What are your thoughts on such methods?

Yagi:Well, it is often said that major sake breweries use IT to brew their sake, and some people think that everything is made by machine, but that is not true.

When I first came back to Japan, I went to visit a major sake brewery and found that they only use computers to control the amount and timing on the sake making so that the taste is not blurred, but each process is still done by hand.

So you are saying that human hands are important for good sake?

Yagi:I agree. It takes a lot of time and effort to make truly delicious sake unless it is made in small batches.

“Yeast starter making" is the process of adding yeast to steamed rice, water, and koji

Koji is made by sprinkling koji over steamed rice and allowing it to propagate

For what it's worth, Yamatan Masamune is not that expensive, is it?

Yagi:Yes, this can't be helped, but there are more than 1,000 makers in Japan, and they are all crowded together in an ever-shrinking market, so the market price is low. The best selling price range for sake is about 1,500 yen in Tokyo and around 1,000 yen over here. Considering the amount of effort that goes into the production, the price should be higher, but it is not possible. It is a tough industry.

Winning awards at competitions is the way of communicating the deliciousness of products

Yamatan Masamune has won many awards in competitions, hasn't it?

Yagi:We win awards partly for our own study, but also for the future.

Sake is a luxury item, so having some kind of endorsement is a reassuring.

The sake industry is the ultimate word-of-mouth marketing world. You have never seen commercials for Otters, Kuroryu, or other sake brands that are now considered delicious, have you? Even if I try my best to say, "It's delicious! but people think that you are just saying. However if we win an award, people think that our sake has been recognized.

You are really thinking a lot strategically. What was the story behind your being selected for ANA's First Class?

Yagi:In 2014, we won the highest gold medal in the “Delicious Sake in a Wineglass Award,” and out of the 9 sake products that won the highest gold medal, 3 were selected for ANA's first class.

So you were chosen as one of the three winners.

Yagi:Yes, that's right. I was very happy. I think it shows how hard ANA and JAL worked to build their brands. After all, when an airline chooses a product, sales explode.

Ginjo-shu (right) chosen in ANA first class and

“SHIZUKUHIME” attaining popularity overseas

You are also expanding your business overseas, aren't you?

Yagi:About 10 years ago, I decided that I wanted to sell our products overseas, so even though I had no idea where to start, I went to Shanghai to look for sales offices and steadily began selling our products there. Now, our products are sold in 10 countries. The majority of our sales are in China, Hong Kong, and Taiwan, and recently, it has been increasing in Canada.

You are making an effort, Mr. President! Has the soil been created for sake to be sold overseas?

Yagi:There is a Japanese food boom, so the sake industry as a whole is growing. In that sense, it's easier to sell now.

By the way, which brands sell the best?

Yagi:Preferences vary from country to country. The countries that drink a lot of wine are different from those in Asia. The price range that sells also differs. For example, Chinese people like junmai ginjo. In our case, a junmai ginjo sake called “Shizuku Ehime” priced at 1,450 yen sells relatively well. It is fruity and has a firm body, like a white wine, and goes well with meals.

The ginjo-shu used in ANA's first class also won the “Best Sake in a Wine Glass” award, which means it must be popular overseas?

Yagi:If anything, that one has a more floral aroma, a lighter mouthfeel, and a thinner body. It is a good aperitif or starter.

Are you planning to expand overseas?

Yagi:Yes, but there are limits to what I can do, so once I get to the U.S. and the U.K., I would like to go in the direction of deepening our relationship with each country, not expanding any further.

It is true that there are not that many people in the company. Are the people who were making sake earlier all employees of the company?

Yagi:Yes. All of them are our employees, but actually that is only starting this year. Until last year, we had so-called seasonal toji (master brewers) come in and make sake using our facilities on consignment from us. What's different is that now we can keep changing things. We can now change the equipment and do things through trial and error.

So, you are going to be able to make it taste better from now on?

Yagi:Yes. I would like to keep improving the quality of sake from now on.

I am looking forward to it. Thank you very much for your time today.

Everyone involved in sake brewing at the YAGI-SYUZOUBU.

The toji (master brewer) is the second from the left.

*The products and services introduced in this article are intended for people aged 20 and over.

Drinking alcohol is not recommended for minors or those who are pregnant or breastfeeding, due to legal and health reasons.